Why choose Aluminum Casting over competing processes

Wiki Article

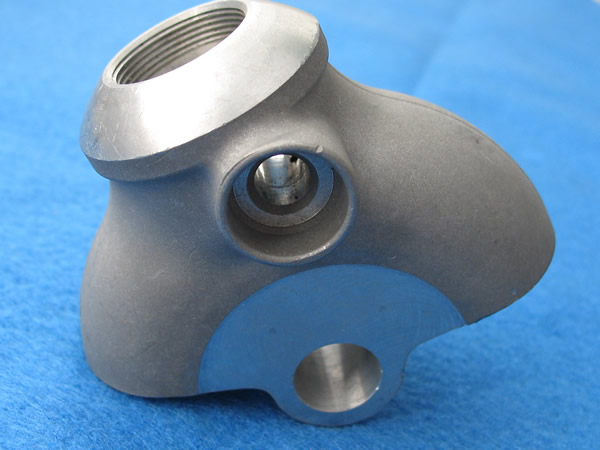

Exploring the Benefits of Using Aluminum Castings in Modern Production

Aluminum castings have actually ended up being increasingly pertinent in contemporary manufacturing due to their unique residential or commercial properties. The light-weight nature of aluminum enables a lot more elaborate layouts, specifically beneficial in markets such as automotive and aerospace. Its rust resistance expands item life-span, while cost-effectiveness enhances production performance. These advantages invite a closer assessment of aluminum's function in different applications and its influence on style flexibility and sustainability in manufacturing procedures.Light-weight Qualities and Their Impact on Style

The lightweight properties of aluminum castings significantly affect modern-day design practices across various markets. Designers and engineers usually prioritize weight reduction in their projects to boost effectiveness and efficiency. This particular permits the development of complex forms and designs that would certainly be testing with larger products. In industries such as vehicle and aerospace, where every gram counts, aluminum castings add to fuel efficiency and reduced discharges. Furthermore, the simplicity of producing procedures like die casting allows the manufacturing of complicated geometries, causing ingenious item styles. The capability to balance toughness and weight makes aluminum an attractive choice for producers seeking to optimize item functionality while reducing manufacturing costs. As industries remain to evolve, the fostering of aluminum castings is most likely to broaden, promoting brand-new chances for style creative thinking and design developments. Overall, the light-weight nature of aluminum is an essential consider shaping modern-day production practices.

Superior Deterioration Resistance for Long Life

Although several products experience destruction gradually, aluminum castings attract attention for their exceptional corrosion resistance, substantially enhancing the durability of items. This resistance is largely associated to the all-natural formation of a safety oxide layer on the aluminum surface area, which prevents additional oxidation and protects against rusting. Unlike steel or iron, aluminum does not wear away easily when exposed to moisture or various chemicals, making it an excellent choice for applications in extreme settings.In enhancement, aluminum castings preserve structural honesty over expanded periods, decreasing the requirement for regular replacements. This dependability is critical in sectors such as automobile, aerospace, and aquatic, where part failing could cause substantial safety issues. By choosing aluminum castings, makers can ensure that their items not just sustain the test of time however also carry out consistently under tough problems, inevitably benefiting both producers and end-users through boosted sturdiness and fewer upkeep needs.

Cost-Effectiveness in Production

Cost-effectiveness in aluminum casting manufacturing is driven by numerous crucial aspects. Lowered product waste adds to decrease manufacturing costs, while rapid production times boost general effectiveness. These components jointly place aluminum castings as a viable option for manufacturers looking for to enhance their operations.Reduced Product Waste

Lowering material waste in aluminum casting not just enhances sustainability yet likewise considerably lowers manufacturing expenses. Efficient usage of raw products is essential in contemporary production, where minimizing waste can result in significant financial savings. Aluminum casting procedures enable for intricate designs with specific requirements, which aids to maximize material usage and lower unwanted. Strategies such as near-net shape casting even more restrict the quantity of scrap created during manufacturing. Additionally, the recyclability of aluminum adds to a reduction in waste, as leftover products can be melted and recycled in future applications. By adopting aluminum casting techniques, suppliers can accomplish not just a more eco-friendly procedure yet also a streamlined manufacturing procedure that maximizes resource effectiveness and lowers overall material expenses.Lower Production Costs

Quick Manufacturing Times

While many factors add to the overall effectiveness of manufacturing processes, quick production times attract attention as a significant advantage of aluminum casting. This technique enables the fast creation of elements, considerably decreasing lead times. The capability to generate complex forms with high precision suggests that manufacturers can swiftly reply to market demands and range manufacturing as required. Additionally, aluminum's positive thermal residential properties make it possible for quicker cooling prices, further speeding up the total casting procedure. Shorter production cycles lead to enhanced stock turn over and reduced operational costs. By lessening delays and improving throughput, aluminum casting supports a more nimble manufacturing atmosphere, inevitably adding to boosted competitiveness in the market.Style Flexibility and Complicated Geometries

Aluminum castings supply remarkable layout adaptability, making it possible for the development of complex geometries that would be challenging with other materials. This capacity permits makers to create lightweight structural options that boost overall performance and performance. Additionally, the fast prototyping possibility of aluminum castings increases the development procedure, helping with development in design.Intricate Layout Capabilities

Lightweight Structural Solutions

Makers significantly utilize aluminum castings to supply light-weight structural solutions that do not compromise on stamina or sturdiness. The fundamental buildings of aluminum, including its reduced density and high strength-to-weight proportion, make it an excellent selection for applications where weight decrease is crucial. This light-weight particular facilitates design flexibility, permitting engineers to create complex geometries that typical materials may not suit. Additionally, aluminum castings can be customized to particular efficiency demands, improving performance without adding too much weight. This versatility enables the manufacturing of detailed elements for various sectors, such as aerospace and vehicle, where effectiveness and performance are critical. Overall, aluminum castings play click over here now a vital function in advancing modern production via ingenious architectural styles.Rapid Prototyping Prospective

Fast prototyping has arised as a game-changer in contemporary manufacturing, specifically when it pertains to develop versatility and the capability to produce complex geometries. Aluminum castings promote this technology, enabling engineers to generate intricate designs that would be challenging or impossible with traditional approaches. The light-weight nature of aluminum improves the simplicity of adjustment during the prototyping stage, allowing quick versions and modifications. Moreover, the product's excellent thermal conductivity and corrosion resistance contribute to the longevity of models, making them ideal for testing in real-world conditions. As a result, makers can accelerate item growth cycles, reduce expenses, and boost development. Eventually, the assimilation of aluminum castings right into quick prototyping procedures sustains the production of innovative, high-performance components tailored to specific applications.Improved Thermal and Electric Conductivity

While aluminum castings are renowned for their lightweight residential properties, their boosted thermal and electric conductivity additionally plays an important function in modern-day production. This particular makes aluminum an ideal choice for discover this applications requiring efficient heat dissipation and electrical performance. As an example, components in electronic devices gain from aluminum's capacity to properly move warmth, consequently lessening the threat of getting too hot and lengthening tool life expectancy. In automotive and aerospace markets, aluminum castings contribute to improved thermal monitoring systems, advertising power effectiveness.Additionally, the high electrical conductivity of aluminum permits its prevalent use in electric components, such as ports and bus bars. This function not only lowers energy loss throughout transmission yet likewise enhances total efficiency. The combination of these buildings settings aluminum castings as a preferred product in many applications, driving innovation and effectiveness in manufacturing procedures throughout numerous markets.

Sustainability and Environmental Benefits

Aluminum castings offer considerable sustainability and ecological benefits, aligning with the growing focus on eco-friendly production practices. One of the key advantages of aluminum is its recyclability; approximately 95% of aluminum can be recycled without shedding quality. This procedure consumes just a portion of the energy needed for primary manufacturing, considerably reducing greenhouse gas discharges.In addition, aluminum is lightweight, which adds to power efficiency in transport and item usage. Its longevity and resistance to corrosion prolong the life expectancy of products, lessening waste and the demand for regular replacements. The use of aluminum castings can lead to much more effective manufacturing procedures, as they usually call for much less power and material contrasted to traditional approaches.

Applications Across Different Industries

As sectors significantly seek versatile materials for ingenious applications, aluminum castings have become a prominent option throughout numerous sectors. In the automobile market, lightweight aluminum castings add to enhanced fuel efficiency and performance, while in aerospace, they supply toughness without jeopardizing weight, crucial for airplane layout. The customer electronic devices field advantages from aluminum's outstanding thermal conductivity, making it excellent for warmth sinks and enclosures. On top of that, the construction industry utilizes aluminum castings for home window frameworks, roof elements, and architectural components as a result of their toughness and resistance to rust. Additionally, the clinical devices industry relies on aluminum castings for producing exact, lightweight components that fulfill stringent health requirements. These varied applications highlight the adaptability of aluminum castings, making them a preferred material for suppliers aiming to introduce and enhance item performance across numerous fields.Regularly Asked Questions

Just How Are Aluminum Castings Produced in the Manufacturing Refine?

Aluminum castings are created via a process entailing melting aluminum, pouring it right into molds, and permitting it to solidify. Aluminum Casting. This approach enables the development of complex shapes and specific dimensions called for in various applicationsWhat Precaution Are Needed When Working With Aluminum Castings?

When working with aluminum castings, crucial precaution include using protective equipment, ensuring proper air flow, applying fire safety and security methods, and preserving devices to stop mishaps, therefore protecting employees versus possible risks connected with the casting procedure.Can Aluminum Castings Be Recycled, and How Is This Done?

Aluminum castings can undoubtedly be reused properly. The process involves gathering scrap aluminum, thawing it down in furnaces, and after that changing it right into new products, consequently conserving resources and minimizing ecological influence in production.What Are the Common Defects in Aluminum Castings and How to Prevent Them?

Typical problems in aluminum castings include porosity, shrinkage, and surface area imperfections. To stay clear of these problems, correct mold and mildew design, temperature control, and product choice Read Full Article are essential, making sure ideal casting problems and reducing the chance of issues.How Do Aluminum Castings Contrast to Various Other Materials in Regards To Stamina?

Aluminum castings display beneficial strength-to-weight proportions contrasted to lots of materials - Aluminum Casting. While generally less solid than steel, they outshine plastics and supply enough stamina for different applications, making them a versatile choice in manufacturing processesReport this wiki page